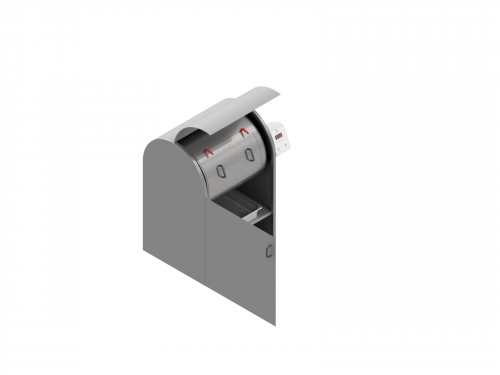

Solid testing drums for coke, iron ore and sinter (ligno tester/ligno meter). Model: LT-600

Manufacturer: 12050.00 EUR

Find our dealer prices: dnd.instruments@gmail.com

SPECIFICATIONS:

Dimensions: 1000х1200х800

Weight: 90 kg

Test drum:

Inner diameter: 598 mm

Length along the inner edges: 598 mm

Departure of the partition: 200 mm

Cover: 635x300mm

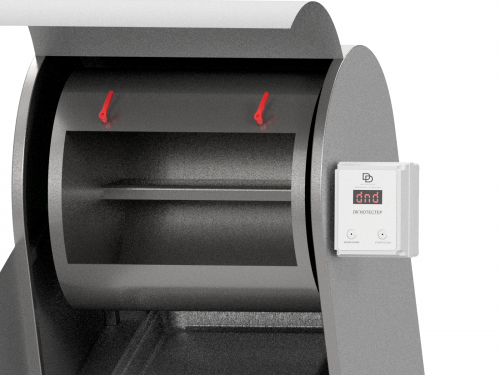

Transmission and control: round belted transmission, based on collector AC motor witch controlled by MCU.

Regulation of rotation frequency - triac, electronic.

Drum rotation frequency: 21 +/- 0.1 rpm

Speed control: electronic speed sensor

Damping system: passive 2-stage on longitudinal and transverse shock absorbers.

SPECIFICATIONS:

Dimensions: 1000х1200х800

Weight: 90 kg

Test drum:

Inner diameter: 598 mm

Length along the inner edges: 598 mm

Departure of the partition: 200 mm

Cover: 635x300mm

Transmission and control: round belted transmission, based on collector AC motor witch controlled by MCU.

Regulation of rotation frequency - triac, electronic.

Drum rotation frequency: 21 +/- 0.1 rpm

Speed control: electronic speed sensor

Damping system: passive 2-stage on longitudinal and transverse shock absorbers.

Description

Ligno tester/ligno meter, model: LT - 600 (round drum). For testing according to EN15210 - 2.

It is used to test compound feed, solid biofuel or any material in the form of granules for abrasion and strength.

Model LT - 600 also allows testing of fuel briquettes.

Preliminary preparation of the device:

- When turning on the device for the first time, it is necessary to remove all packaging materials, as well as conduct a visual control of the integrity of the equipment.

- Connect to the network with a 220V cable (included).

Working with the device:

- Turn on the power with the "Network" button;

- Open the bottom cover (door) by pulling the handle toward you. The top cover (hood) will be opened automatically, because these parts are mechanically connected to each other. In the upper and lower position, the lid is held by a gas stop (shock absorber) according to the principle of how a door rises in furniture;

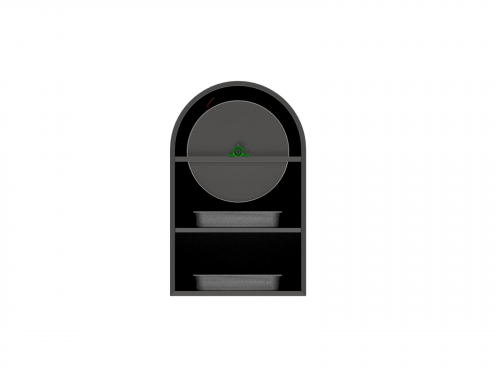

- Turn the drum cover latches and remove the cover. Handles are provided for removal;

- ЗPour the pre-weighed sample into the drum;

- Close the drum cover in reverse order and close the front door;

Pay attention!

To start the device, the upper cover must be closed.

If it is opened during the operation of the device, the engine will stop working and the test cycle will have to be performed again.

- Press the "start" button - the current value of the remaining revolutions is displayed on the device indicator, the engine starts and starts rotating the drum at a standardized speed of 21 rpm; The reading accuracy - 0.1 rpm is regulated by the built-in rotation sensor.

After the end of the rotation, the drum will be installed in a position convenient for the user.

- Open the front door;

- Release and remove the drum cover;

- Remove the sample by pouring it into a tray using a brush (the tray and brush are included);

- After finishing work, turn off the device by pressing the "Network" button